There are three main types of steel hardening that Northern Heat offers: case hardening, through hardening, and flame hardening.

Case Hardening

Also known as case carburization, case hardening involves hardening the outer surface of the steel while keeping the ductility and hardness of the interior the same. This process is usually performed on low-carbon, softer steels that require strengthening.

One of the standard industrial processes for case hardening is flame hardening, which involves heating the surface to extremely high temperatures and then cooling the metal rapidly.

Hardening the outer surface is more efficient than hardening the entire metal, resulting in considerable cost savings. This hardening technique is essential for manufacturing parts that must resist abrasion but be able to absorb impacts without fracturing. These components include gears, pins, rods, camshafts, fasteners, cooking utensils, and tools that encounter a lot of wear and tear.

Through Hardening

Through hardening is the process of strengthening and hardening the entire cross-section of the steel, not just the outer layer. It involves heating the steel, quenching it rapidly in oil or water, and reheating it to reduce surface brittleness. Some applications of through hardening include:

- Automobile components

- Hand tools: screwdrivers, hammers

- Load-bearing parts: chains, brackets, bolts, nuts, axles, springs, bearings

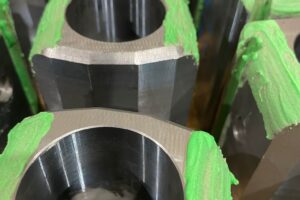

Flame Hardening

Like case hardening, this process strengthens steel by heating the outer layer to very high temperatures. Flame hardening is a specific type of hardening that utilizes a flame in an industrial furnace to harden the metal. Once it reaches about 850 °C, the steel is quenched with water or a synthetic substance, which quickly hardens the surface to a depth of 1 to 10 mm. Typical flame-hardened products include blades, gears, wear plates, hand saws, cams, and certain automotive components.