Northern Heat Treat Ltd. specializes in providing heat treatments to harden, strengthen, and optimize metal parts for our metal shop and fabrication customers. Professional heat treatments can improve the strength and dimensional integrity of sheet metal, metal components, and finished products over time so they provide consistent, reliable performance. Metal formers and manufacturers use a wide range of heat treatments, such as annealing and stress relieving, that confer unique attributes or advantages to the metal. Learn more about the differences between annealing and stress relieving, their unique benefits, and how Northern Heat Treat can help with your next project.

Annealing vs. Stress Relieving

Through a three-step technique, annealing heat treatments soften metal and increase its ductility. Our process starts with a recovery stage, where we heat a metal workpiece to a temperature below the recrystallization point to relieve internal stress. Next, we continue heating the metal until the temperature rises above that point during the recrystallization stage so that the material’s crystalline lattice microstructure can begin to reform. Lastly, we allow the workpiece to cool as part of what’s called the grain growth stage. These steps allow us to reduce imperfections in that crystal lattice, resulting in a more pliable and formable material. This improves the workability of the metal so that manufacturers can create complex or intricate parts with a reduced risk of cracks, imperfections, or dimensions that fall outside of accepted specifications and tolerances.

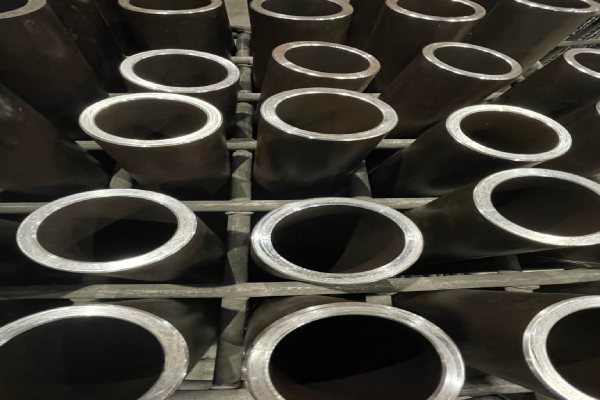

Stress-relieving processes also involve heating up the metal. However, we keep the temperature below its individual recrystallization point. This process removes the stress that has built up in the metal forms throughout manufacturing, such as from gas cutting, cold working and bending, welding, and other mechanical processes. That inbuilt stress can increase the risk of premature part failure, distortion, and poor performance under pressure, so removing the stress without modifying the crystalline microstructure of the metal improves the longevity and quality of workpieces. Once again, we allow the material to cool, and this process ultimately removes approximately 90% of internal stress in a component.

Benefits of Annealing and Stress Relieving

Both annealing and stress relieving help fabricators enhance the dimensional stability and workability of steel and other metals, though these processes produce separate end results and achieve them differently. The core benefit of stress relieving is the removal of internal stresses in a worked metal piece that can cause distortion or breakage if left untreated. While annealing also provides stress relief, it goes beyond that by actually altering the microstructure and the mechanical characteristics of the metal itself, making it more pliable.

Key Service Features: Annealing and Stress Relieving

At Northern Heat Treat, we provide comprehensive heat treating services that reduce stress in metal parts and increase the positive mechanical characteristics of the material.

Annealing

Our annealing processes are designed to consistently correct flaws in a metal’s crystalline microstructure without melting the metal. During the process, our engineering technicians heat the metal so internal stress is relieved and, as the temperature continues to rise, flaws in the crystal structure are repaired. Then, we cool the metals at a controlled rate to manage the growth of new grains within it, based on the specific material. This reduces dislocations in the crystal structure.

Stress Relieving

Our stress relieving process starts with heating metal workpieces to an appropriate temperature below their recrystallization point. This allows the internal stresses from machining and manufacturing to dissipate without affecting the mechanical properties of the metal or its microstructure. Performing a controlled cool ensures the temperature of a workpiece doesn’t drop too quickly or unevenly.

Annealing and Stress Relieving at Northern Heat Treat

Heat treatments like annealing and stress relieving can produce a wide range of positive effects in metal workpieces. At Northern Heat Treat, we know that different steels and other materials require different temperature ranges, and our heat treatments can increase the quality of metal materials and products by:

- Removing over 90% of the internal stress from earlier manufacturing stages

- Making metal more ductile and workable

- Reducing brittleness in steel

- Increasing hardness and strength after manufacturing is complete

We are proud to offer the largest stress relief furnace in our region, the newest addition to our facility in Ontario, Canada, to add to our current furnace capacity for taking on additional volume as well as larger workpieces. Northern Heat Treat also offers an array of additional heat treatments, including:

- Case hardening

- Through hardening

- Air hardening

- Induction hardening

- Straightening

Partner With Northern Heat Treat

Let the team at Northern Heat Treat be your resource for reliable annealing and stress relieving services. As an ISO 9001-certified company, we are committed to quality, and our team is backed by over three decades of experience in our field. Contact us today to learn more about our capabilities or to start your order.